*W* Data for recursed qualities missing for components of pool S1# at RR. Values assumed ZERO.

Do you see messages like this when you run your model? They would be at the top of the report (or the end of the LST file if you were trying to hide all the warnings by setting NORTEMSG.) The warning is only issued for pool properties that are used somewhere in the model – where there is a process unit input or blend specification that requires it, on that pool or one downstream of it. Often these are properties that have been set up to track the composition or origin of material – such as if it is cracked or not, so most streams will be zero – which is probably why someone didn’t bother to fill it in. But that isn’t always the case, particularly when you have been adding structure – so its worth checking.

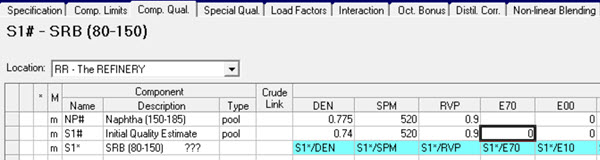

If you have a database model it is often enough just to open the component quality panel for the pool in question and see what isn’t there. Where a value appears in the Pools “Initial Quality Estimate” row, then that column should be filled in for every component.

Here we can see that E70 is missing for NP#. Since the IBP is 150, the % distilled at 70 degrees is almost certainly 0, so fill that in. There isn’t a red dot on the row, since the missing value is only a potential issue if the quality is actually needed. Working that out requires tracking it through the blend and process unit data – and so is more efficiently done during the matrix generation step. If there are a lot of missing properties or you are struggling to come up with a good value for some of the components, then you might want to check which properties are actually needed and triggered the warning.

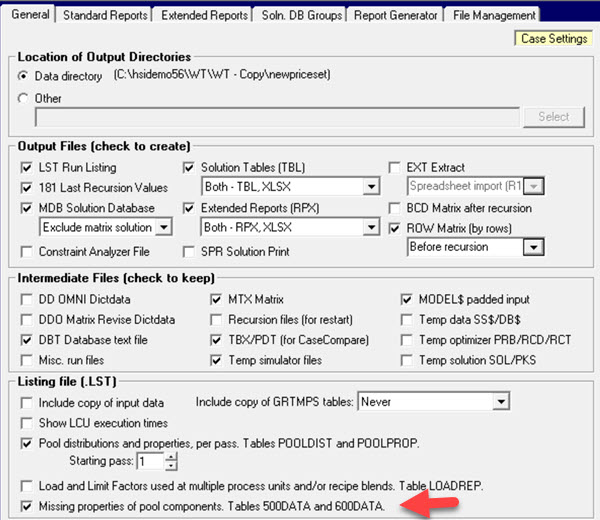

There is a debug option that can be set to request that tables of missing qualities are included in the LST file for the run. You will find it near the bottom of the Output: General panel. (This corresponds to POOLDATA in TABLE OPTION.)

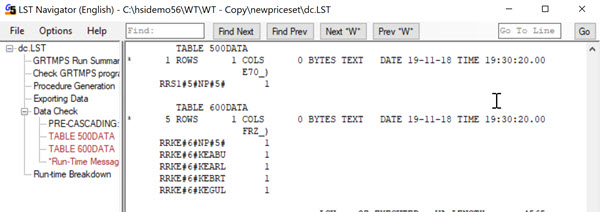

Then if you have any messages about missing qualities you will find TABLE 500DATA for missing gasoline properties and / or TABLE 600DATA for missing distillate properties in the LST file. (If you did a full run, they will be in the Matrix Generation section.)

Now you can see specifically what needs to be filled in. The column is the quality code. The row is (LL)(POL)(5/6)#(STRSS) – where LL Is the location code followed by the pool name with its identifying padding followed by the component name. You can see in the 600DATA section that the KE# pool – which is the straight run kerosene – is missing FRZ, freeze point. If the component name ends with a crude code then it is the expansion of a crude specific stream – so KE* expanded for crudes ABU, ARL, etc. This may well be something you have to add to your crude database – although if it is the same value for the stream whatever crude its from, then you can fill in a fixed value for the “*” stream in the master data instead of putting it in the crude library.

Adding a quality estimate for a pool might lead to more messages about its components as that quality then becomes necessary. When we fill in the E70 value for NP#, for example, the next run might produce a message that its components are missing qualities. So it can take a few turns to completely resolve all the messages.

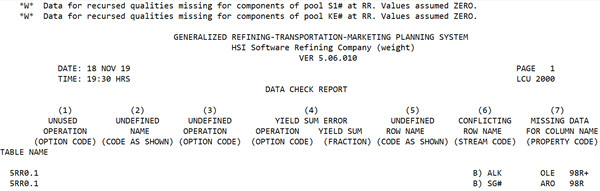

The Run Time warning only is given for pools. For blended products, the Datacheck report will also list components missing properties that are needed for specifications. (Why two separate systems? Pools were added to GRTMPS later and had a different data structure.). These will also effectively be zero.

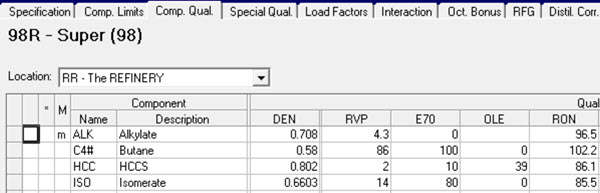

ALK is missing an OLE value at location RR that is needed for product 98R and others. (The “+” means there are others.)

For products you don’t have an initial value row to compare too, but if you look at the component quality panel without the “Show All Qualities” button ticked, then the panel will filter to only those which have a specification. Then the grid should be completely filled in. Once the value has been added, it will be available for the other products too, of course, so you don't need to check them all.

Be warned that filling in missing values, even just with zeros can have an effect on the solution as it may add some quality balance rows to the model. That can be enough to nudge it into a different recursion path. So this is the sort of thing you want sorted before you start any study where you want to compare cases. You may be tempted to leave well enough alone, but it is a really good idea to clear out as many warnings as you can – not only in case there is an actual error in there – but also so that when a new message appears that is telling you something you need to know, you actually notice it.

These missing qualities ones are pretty easy to get rid of – so no excuses – get in there and sort them out!

From Kathy's Hotel Room,

Gothenburg, 19th November 2019.

Gothenburg, 19th November 2019.

Comments and suggestions gratefully received via the usual e-mail addresses or here.

You may also use this form to ask to be added to the distribution list so that you are notified via e-mail when new articles are posted.

You may also use this form to ask to be added to the distribution list so that you are notified via e-mail when new articles are posted.